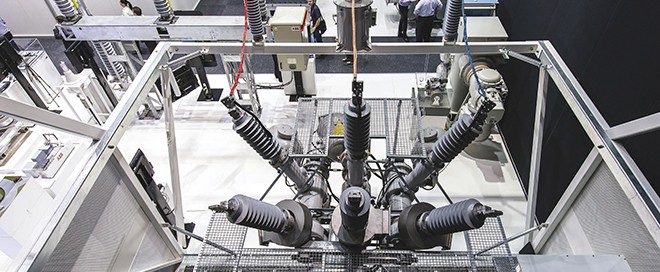

66kV modular substation

Remote Power Transmission System

The ABB Substation forms part of a standalone power transmission substation system, specifically for transmission and distribution of 66kV High Voltage. It transforms 66kV High Voltage to lower useable voltages in mining, industrial and utility applications.

It is a recognizable, branded ABB product that is safe, aesthetically appropriate, and customizable for modular expansion whilst improving on manufacturability, transport, assembly and installation on site. ABB’s Modular Substation can be installed in remote locations quickly and with minimal labor. It is a product designed to be assembled and tested in a factory environment, transported to site, and erected with minimal assembly.

Read More

A Self contained substation solution with reduced installation time and complexity

The 66kV modular substation is a self contained solution. It can be deployed and installed with reduced need for infrastructure or components that are usual in substation installations.

It has integrated features such as auxiliary supply, Battery and Charger and no need for additional external cabling. Many components and operational features are assembled, tested and commissioned in the factory pre shipping, meaning less time and equipment is required during install and commissioning.

Deployment is faster and easier, it is transported to site and erected requiring minimal labor with minimal extra assembly.

A substation that utilizes, Modularity, flexibility, Adaptability and yet Customization

The 66kV modular substation is a modular design that can adapt to the needs of the customer in both initial selection of features and in deployment. The design allows for the product to be expanded using a modular methodology, in order to customize to specific client requests of optional extras.

It is adaptable and can be installed in many scenarios and configurations accommodating customers’ needs. The 66kV modular substation can compliment or replace existing substations installations, or several can be installed together in completely new builds. Different substation configurations can be achieved using the flexibility of the design.

A substation solution that benefits customers by reductions in time, cost and people for implementation and costs to run and maintain

ABB has looked at the value proposition of the modular substation and the potential savings in time and costs the design has enabled ABB to provide to its clients.

Time: Up to 16 weeks less in commissioning compared to other existing products, including personal resources needed on site to assemble and install

Cost: Over $2 Million in savings to customers compared to other existing products, including reduction in loss of revenue due to facility down time and reduced commission time, personal required to install and reduced serviceability due to a quality product.

A substation solution designed for transport that fits on a flat bed truck

The 66kV modular substation is designed for minimal bulk when transported. It was designed to fit within the proportions of a 20ft shipping container and within maximum statutory dimension for transportation on public road without a permit. This would limit the need for using specialised vehicles to access sometimes very remote locations, a great cost saving benefiting the ABB solution.

The product design facilitates minimal dismantling post factory commissioning, for it to be shipped to site. The transport configuration also secures the substation parts into a neat package that can be shipped on one truck.

A substation that brings brand recognition and visual appeal to a generic product market

ABB is acutely aware, that amongst all providers of substation equipment, there is little differentiation visually between many products in the market. There is little emphasis placed upon the aesthetics or branding of these infrastructure products.

ABB saw an opportunity to do something different and stand apart from similar and competing products. Such a physically large product provides a great opportunity to create a design that is visually distinct and creates increased recognition via aesthetics and effective utilization of branding. ABB is a world leader and provide “power and productivity for a better world”. The product should reflect this.