LOADPlus™ Underground Controller

HMI and Graphic User Interface

The LOADPlus™ is a control system for the delivery of explosives (in the form of emulsion) in underground and aboveground mining operations.

The LOADPlus™system has been designed to automate the loading of holes for development and production blasting, delivering explosives faster, more accurately and efficiently. The ruggerdised system is used in operating scenarios from elevated work platforms underground, exposed to falling rock, acidic water and corrosive substances to above ground operations prone to extreme temperature ranges. The outcomes are more efficient, reliable and accurate loading and more predictable blast detonations which improve the safety and production capabilities of mines worldwide.

Read More

Accurate Blasting and Delivery

The LOADPlus™ system controls the operation of pumps, valves, hose pushers and other devices via a CAN (Control Area Network). The enclosure links to the network via a custom connector which also supplies power to the device.

Rock blasts information is planned by engineers using Orica’s Shot Plus software, which is then uploaded to the LOADPlus™. The pre-programmed information specifies the appropriate volume and speed at which explosive product is delivered to the hole to optimise the blast’s effectiveness. The system considers pump rates and calibration data to improve reporting to mine managers and increase the accuracy of blast planning.

Ruggerdised Enclosure

The LOADPlus™ has been designed for rough use in extreme environments while still allowing operators to program precise settings. The LOADPlus™ incorporates a CAN based control system and keypad into an environmentally sealed and vented enclosure.

The design includes a spring loaded cover over the screen interface – when closed it protects the screen while not in use, and when open it serves as a protective hood to shield the display from rocks and debris. A clear PU screen cover protects the control system from explosive emulsion and dirt buildup. The entire enclosure can be easily disassembled within minutes for servicing.

User friendly interface

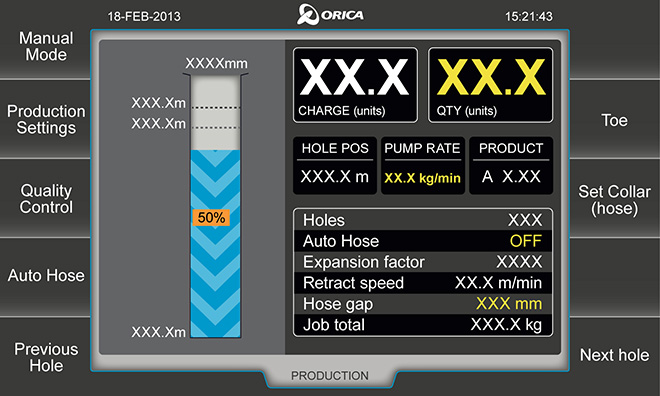

A user orientated design process saw designers at the rock face working with operators and interviewing stakeholders. The goal was to convert a highly technical system into a simple to understand, graphical user interface for the LOADPlus™ system.

A work flow and graphic layout was developed, targeting a reduction in hole loading times and increasing control over loading parameters. The visual layout, design, colour definition and luminosity of the interface considers the wide range of working environments where the LOADPlus™ is used, delivering better clarity and usability, minimal training time and ensuring safe operation of the mining equipment.

Articulated Mounting Arm

Commonly used from an elevated work platform in underground mining environments, the articulated mounting arm has been designed to quickly and easily secure the LOADPlus™ enclosure. The adjustable arm provides the correct interaction angles for all users, which includes a growing number of female operators.

The simplified cam latches allow for large, gloved hand operation and is resistant to damage which may be caused by dirt, mud, small rocks, or explosive emulsion. It also stops accidental removal if locking has not been completed. The mounting head allows the LOADPlus™ enclosure to be easily docked and enables 360° rotation.